Steel Glossary

1.2311 P 20

AISI P 20

| C | Si | Mn | P | S | Cr | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| 0.38 | 0.40 | 1.43 | 0.012 | 0.071 | 1.82 | 0.17 | 0.16 | 0.11 |

Plastic mold steel for medium and large molds. Since this material is pre-hardened to 950-1,100 MPa in its

delivery condition, it is also suitable for parts in general mechanical engineering.

Compared to 1.2312, 1.2311 is polishable and photo-etchable. Both materials can be gas and ion-nitrided,

making them suitable for case hardening.

You can obtain 1.2311 from us as precision flat steel (standard and custom dimensions), as VarioPlan, and as raw material cuttings.

You can also obtain 1.2311 from us individually, according to your specifications, as a finished machined drawing part.

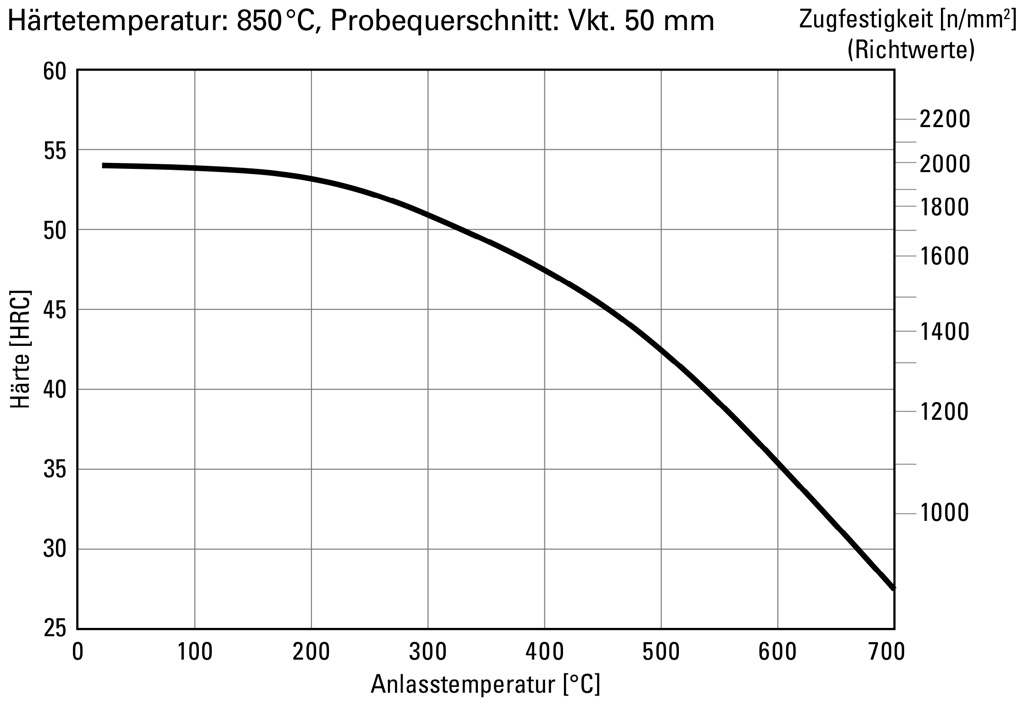

Tempering Chart

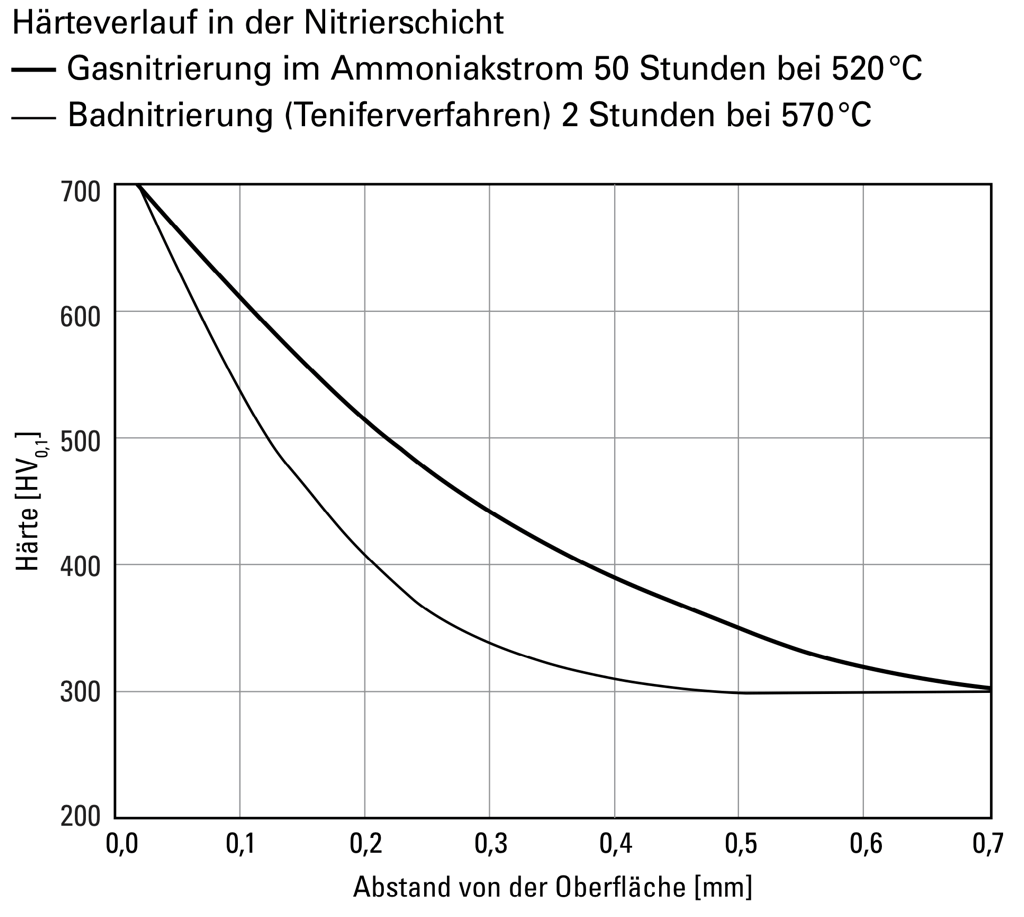

Surface Treatment Nitriding

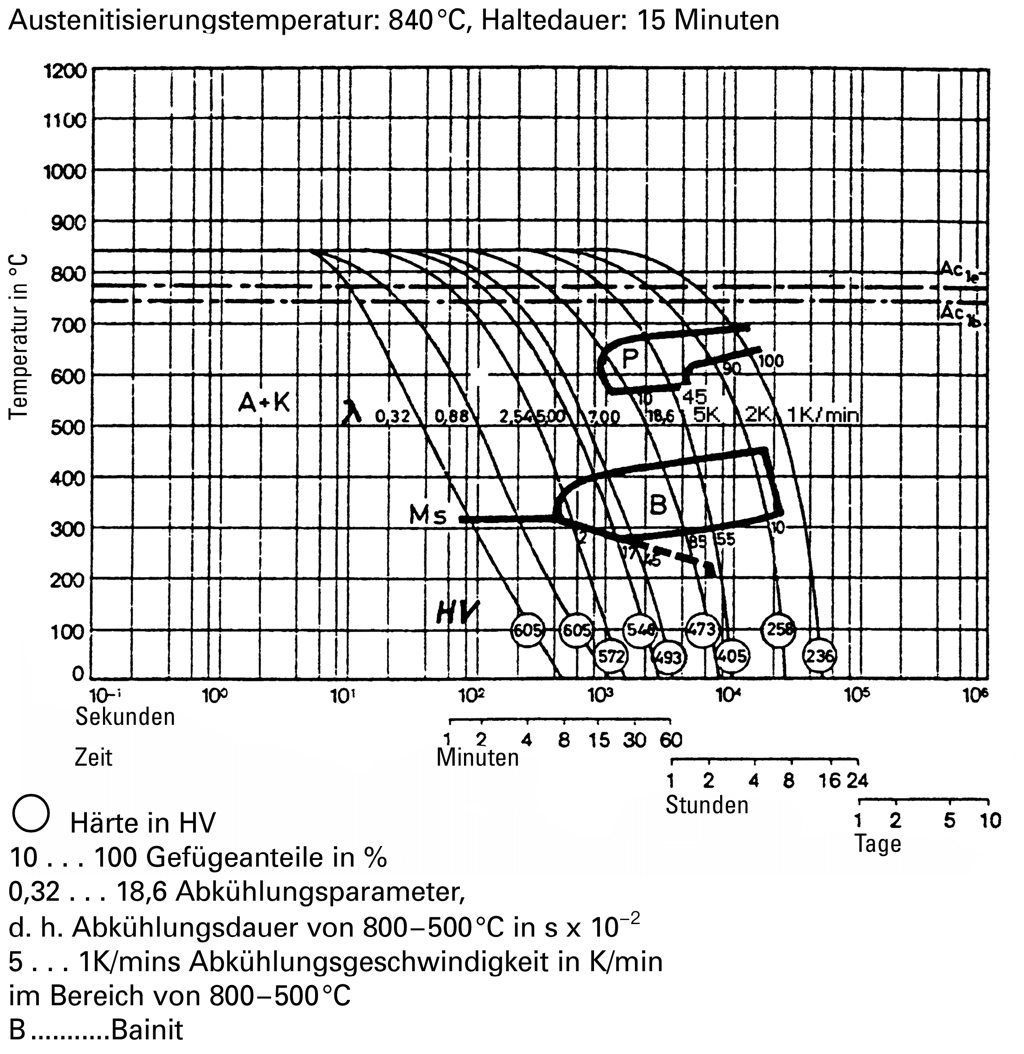

Continous Cooling Transformation Diagramm

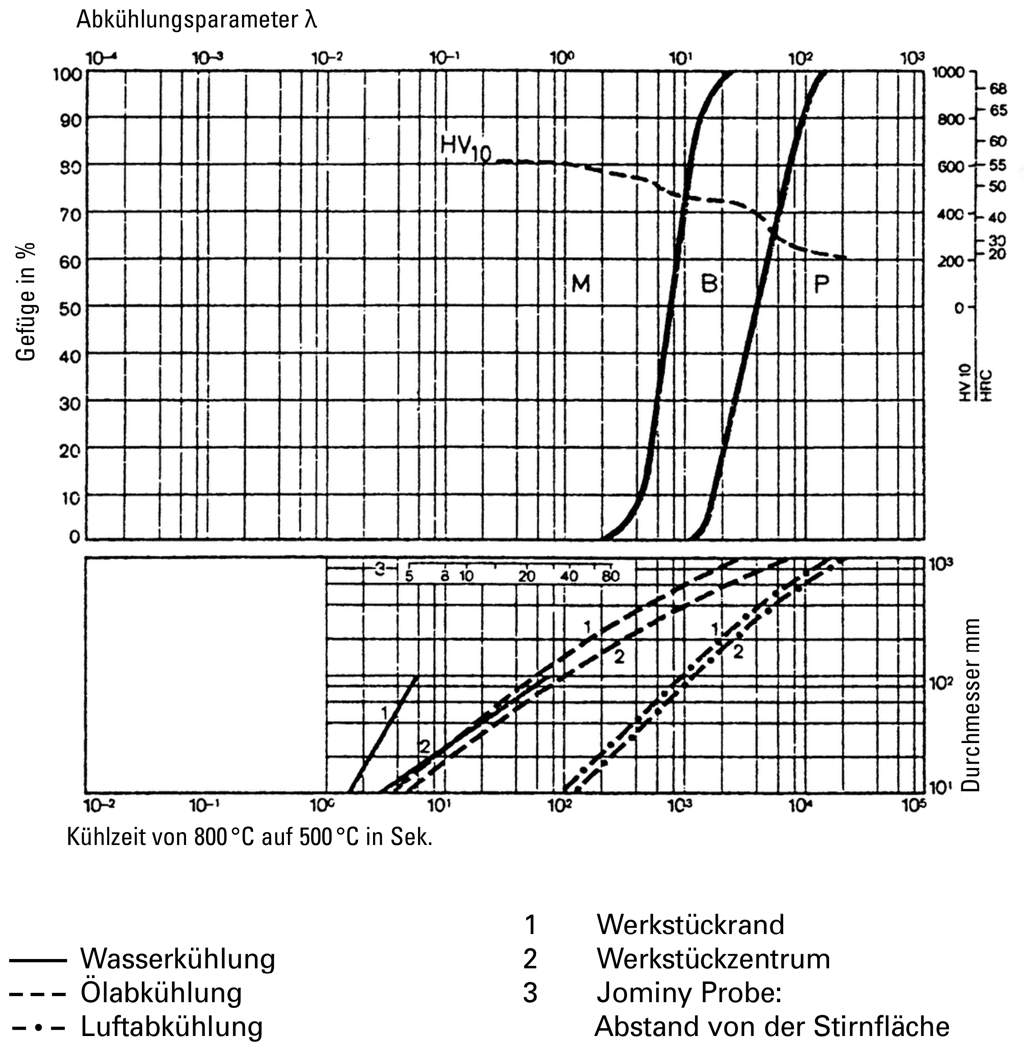

Microstructure Phase Diagram

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.